How Keqiang Achieves Import Substitution in China’s Special Rubber Industry

Import substitution has become a strategic priority in China’s manufacturing sector as industries seek to reduce dependence on foreign suppliers and enhance self-reliance in core materials. In the field of special rubber products—where performance, stability, and durability directly impact the safety and efficiency of applications—achieving import substitution requires more than just matching overseas standards. It depends on technological innovation, quality management, and the ability to provide comprehensive system solutions. Jiangsu Keqiang New Materials Co., Ltd., with more than two decades of deep cultivation in high-performance rubber materials, has become a benchmark enterprise successfully driving this transformation.

Since its establishment in 2001, Keqiang has adhered to an innovation-driven development path. The company invested heavily in research and development from the very beginning, recognizing that special rubber products involve complex formulations, precise production processes, and rigorous testing environments. Many of these products were historically dependent on imports due to technical and performance requirements. Keqiang’s R&D team focused on breakthroughs in silicone materials, special rubber fabrics, and conveyor belt systems, gradually mastering the core technologies that were once dominated by international brands. This capability laid the foundation for Keqiang to undertake import substitution across multiple industries.

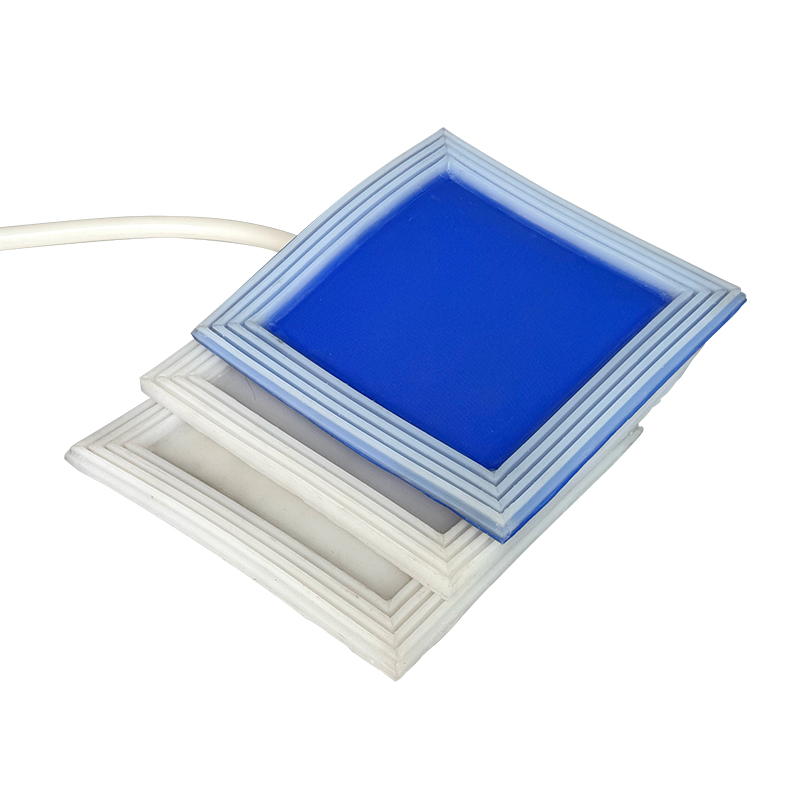

One of the major achievements in Keqiang’s journey is its success in silicone rubber sheet manufacturing. Silicone sheets used in photovoltaic module laminators, vacuum press machines, glass laminating furnaces, and high-temperature processing equipment must maintain stability under extreme conditions. In the past, domestic manufacturers relied heavily on imported silicone sheets for reliability. By optimizing molecular structures, improving production lines, and enhancing thickness uniformity, Keqiang developed silicone rubber sheets that not only meet but often exceed the performance parameters of imported products. Today, these sheets are widely used by domestic and international equipment manufacturers, proving that local materials can replace foreign brands without compromising quality.

Another key area where Keqiang has achieved import substitution is in high-performance conveyor belts. Traditional transmission systems often depended on imported light rubber belts because of their strength, wear resistance, and long service life. Keqiang’s specialized formulation technology, combined with advanced calendaring and coating processes, has enabled the company to produce conveyor belts with excellent flexibility, anti-corrosion performance, and durability. These products now serve industries such as electronics, logistics, packaging, food processing, and precision manufacturing. Their stable performance has convinced many customers to switch from imported alternatives to Keqiang’s domestic solutions.

Special rubber fabrics represent another category where Keqiang has taken the lead in China’s import substitution drive. Rubber-coated fabrics for tunnels, sealing, and protective applications require high tensile strength, weather resistance, flame retardancy, and aging resistance. These technical requirements made such products heavily reliant on imported materials in the past. Keqiang approached this challenge by integrating textile technology with rubber compounding expertise. Through precise coating techniques and strict aging simulations, the company developed special rubber fabrics capable of performing reliably in demanding environments such as tunnels, construction sites, and high-strain engineering projects. These breakthroughs significantly reduced dependence on imported industrial textiles.

What distinguishes Keqiang in the import substitution landscape is not just its product performance but also its commitment to standardization and quality control. As a member of the China Rubber Standardization Committee and a governing unit of the China Rubber and Plastic Machinery Association, Keqiang actively participates in formulating industry standards. This involvement ensures that its products align with both domestic and international benchmarks and contributes to raising the overall level of the industry. It also demonstrates Keqiang’s confidence in the reliability and stability of its materials.

Keqiang’s rise as a national-level specialized and special new technology “little giant” enterprise further validates its technical strength. The recognition from authoritative institutions reflects Keqiang’s ability to offer differentiated, high-value products in specialized fields. By consistently benchmarking international first-line brands and continuously improving its production systems, the company has built a product lineup that can fully replace imported equivalents in many applications. More importantly, Keqiang provides entire system solutions—covering sealing, buffering, anti-corrosion, and transmission—rather than just standalone products. This integrated approach strengthens user confidence in adopting domestic materials.

Looking ahead, Keqiang aims to expand its role in import substitution by deepening innovation, optimizing materials for next-generation industries, and upgrading manufacturing to become even more intelligent and efficient. With a mission of “empowering science and technology, strengthening enterprises, and rejuvenating the country,” the company remains committed to contributing to China’s industrial self-reliance. As global supply chains evolve and performance requirements grow increasingly stringent, Keqiang’s continuous pursuit of higher-quality special rubber products positions it as a leader shaping the future of China’s rubber industry.