Performance Comparison: Keqiang Silicone Sheets vs. Traditional Rubber Sheets

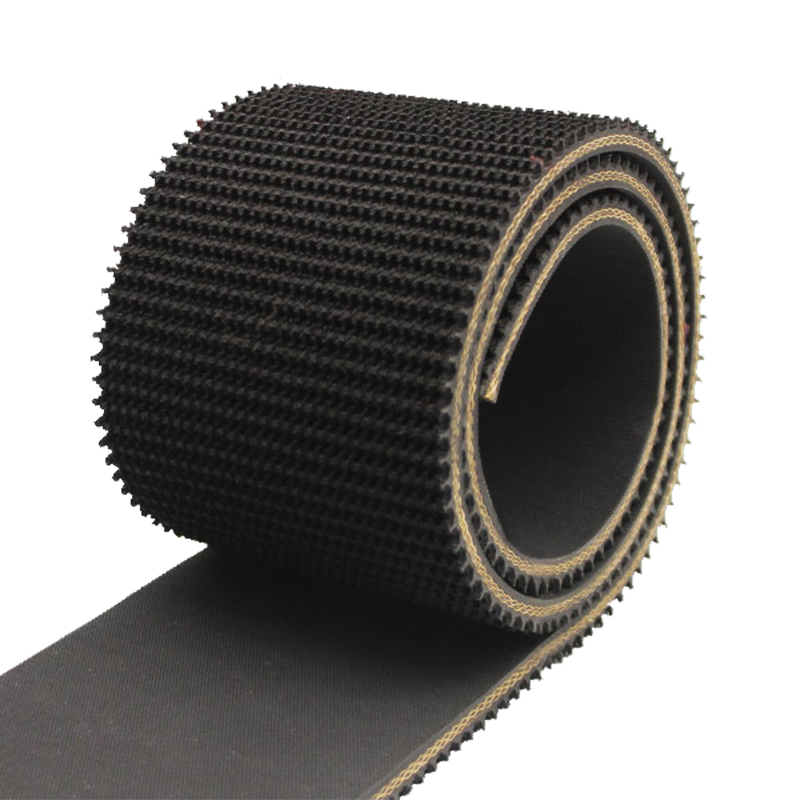

In industrial applications where heat resistance, elasticity, and long-term durability are essential, the choice of rubber sheet material directly impacts production efficiency and product quality. As manufacturing technologies advance, traditional rubber sheets are no longer sufficient for demanding environments such as photovoltaic module lamination, vacuum pressing, glass lamination, and high-temperature composite molding. This has created a rising demand for high-performance silicone sheets—an area in which Jiangsu Keqiang New Materials Co., Ltd. has established a strong reputation. By leveraging advanced material engineering and stringent quality control, Keqiang has developed silicone sheets that significantly outperform traditional rubber sheets in almost every critical category. Traditional rubber sheets, typically made from natural rubber (NR), nitrile rubber (NBR), or ethylene propylene rubber (EPDM), have long been used in industrial applications due to their low cost and general-purpose performance. However, these materials have limitations when exposed to extreme heat, prolonged pressure, or aggressive chemicals. Their molecular structures tend to degrade over time, leading to hardening, cracking, loss of elasticity, and frequent replacement needs. As industries adopt higher production speeds and more demanding processes, these disadvantages have become increasingly problematic.

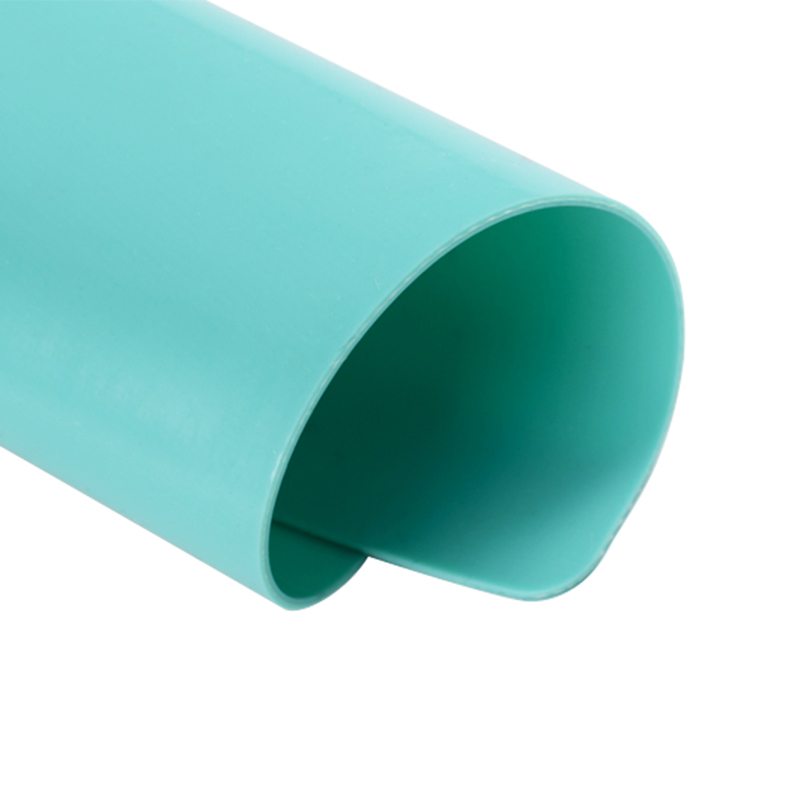

Silicone sheets, especially those produced by Keqiang, offer a significant performance upgrade. One of the most notable differences is thermal stability. Traditional rubber materials typically operate safely up to 80–120°C, beyond which they soften, deform, or lose structural integrity. In contrast, Keqiang silicone sheets can withstand temperatures from –40°C to 250°C without degradation. This exceptional heat resistance allows them to perform reliably in high-temperature laminators, hot press equipment, and other thermal processing systems, ensuring consistent product output. Another major advantage lies in elasticity and compression set resistance. Traditional rubber tends to lose elasticity over time when subjected to repeated compression cycles. This leads to uneven pressure distribution, reduced sealing effectiveness, and ultimately product defects. Keqiang silicone sheets, however, maintain excellent elasticity even after thousands of compression cycles. Their low compression set ensures that the sheets return to their original thickness and shape after each use, delivering uniform pressure throughout every production cycle. This consistency is especially important in PV module lamination, where even minor variations can cause air bubbles, incomplete encapsulation, or surface defects.

Chemical resistance is another area where silicone sheets significantly outperform traditional rubber sheets. Many rubber types degrade when exposed to oils, solvents, UV radiation, or corrosive gases. This weakens their performance and shortens their lifespan. Keqiang silicone sheets, engineered with stable polymer structures, offer excellent resistance to chemicals, oxidation, ozone, and UV exposure. This stability makes them suitable for demanding applications in electronics, new energy, aerospace, and high-temperature manufacturing environments. Durability and lifespan also show clear differences. Traditional rubber sheets often require frequent replacement due to hardening, cracking, or surface degradation. This not only increases material costs but also causes production downtime. Keqiang silicone sheets, however, are designed for long service life. Their high mechanical strength, anti-tear properties, and resistance to thermal aging enable them to withstand continuous and intensive use. For manufacturers, this translates to fewer replacements, lower maintenance costs, and higher productivity.

When evaluating thickness uniformity and surface precision, Keqiang silicone sheets offer superior performance. Traditional rubber sheets can suffer from uneven thickness due to limitations in their production processes. This inconsistency can lead to irregular pressure distribution during use. Keqiang uses advanced calendaring and precision molding techniques to produce silicone sheets with excellent thickness uniformity and a smooth, defect-free surface. This precision enhances lamination quality and reduces the risk of surface marks or defects on final products. Another performance area worth comparing is heat transfer efficiency. Traditional rubber materials often have lower thermal conductivity, which results in longer processing times in laminators and presses. Keqiang silicone sheets are engineered to transfer heat efficiently and evenly across their surface. This improves lamination speed, reduces cycle time, and enhances overall production efficiency. In high-volume manufacturing environments, even small improvements in cycle time can lead to significant cost savings and output increases.

From a sustainability standpoint, Keqiang silicone sheets also hold an advantage. Their longer lifespan and resistance to degradation mean fewer discarded materials and reduced environmental impact. Additionally, because they help improve operational efficiency, they support more energy-efficient manufacturing processes. In the final comparison, traditional rubber sheets remain suitable for basic, low-temperature, and non-demanding applications where cost is the main priority. However, for industries requiring precision, durability, high-temperature resistance, and consistent performance, Keqiang silicone sheets clearly stand out as the superior choice. Their advanced formulation, exceptional properties, and long-term reliability make them an essential material for modern industrial production.

As industries continue to evolve and adopt more sophisticated technologies, the demand for high-performance materials will only increase. With its strong R&D foundation and commitment to quality, Jiangsu Keqiang New Materials Co., Ltd. will remain at the forefront of delivering silicone sheet solutions that significantly outperform traditional rubber alternatives.