Why High-Performance Rubber Is Key to Vibration Reduction in High-Speed Rail

High-speed rail systems represent one of the most advanced forms of modern transportation, combining speed, efficiency, and safety. However, operating at speeds often exceeding 300 km/h introduces significant challenges related to vibration and noise. These dynamic forces affect passenger comfort, track stability, equipment lifespan, and long-term maintenance costs. High-performance rubber materials play a critical role in addressing these challenges, making them a key component in effective vibration reduction for high-speed rail infrastructure. Vibration in high-speed rail originates from multiple sources, including wheel–rail interaction, track irregularities, dynamic loads, and aerodynamic forces. If not properly controlled, these vibrations can transmit through rails, sleepers, fastening systems, and into bridges, tunnels, and surrounding structures. Over time, excessive vibration accelerates fatigue damage, increases noise pollution, and raises safety and maintenance concerns. This is where high-performance rubber materials provide unique advantages over traditional rigid or metallic solutions.

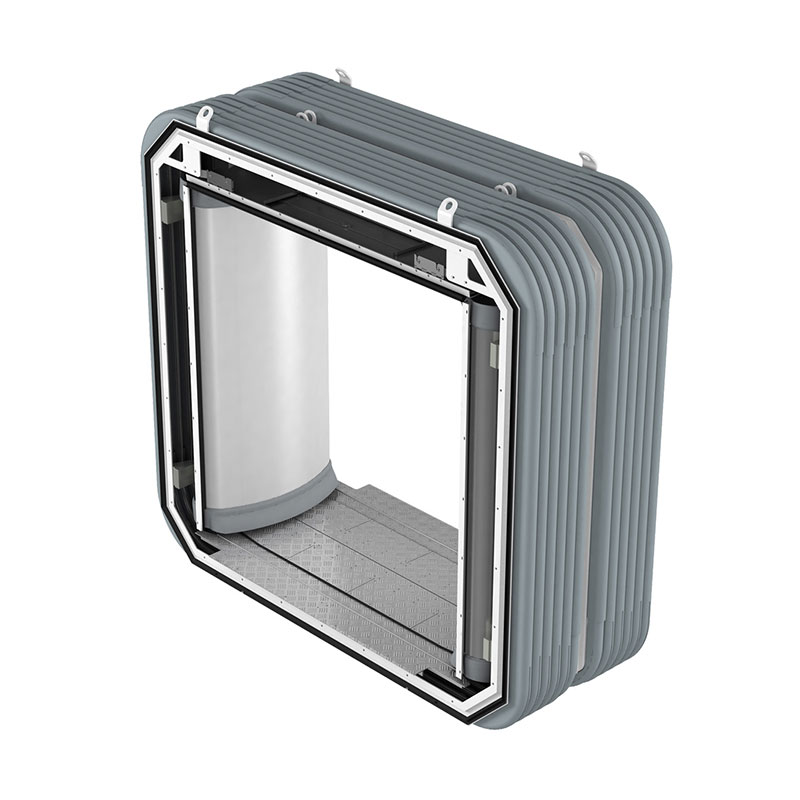

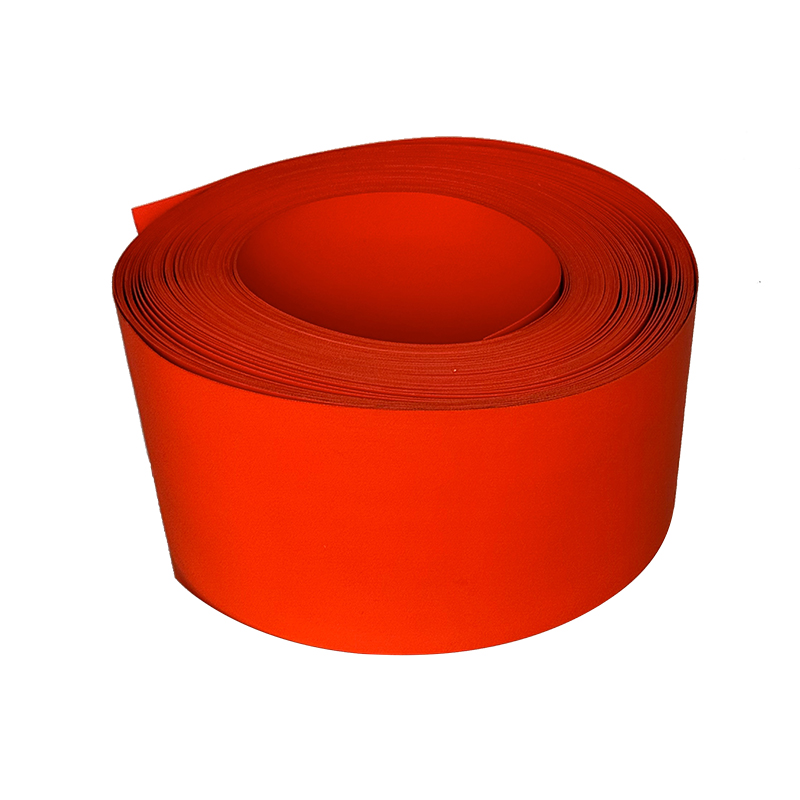

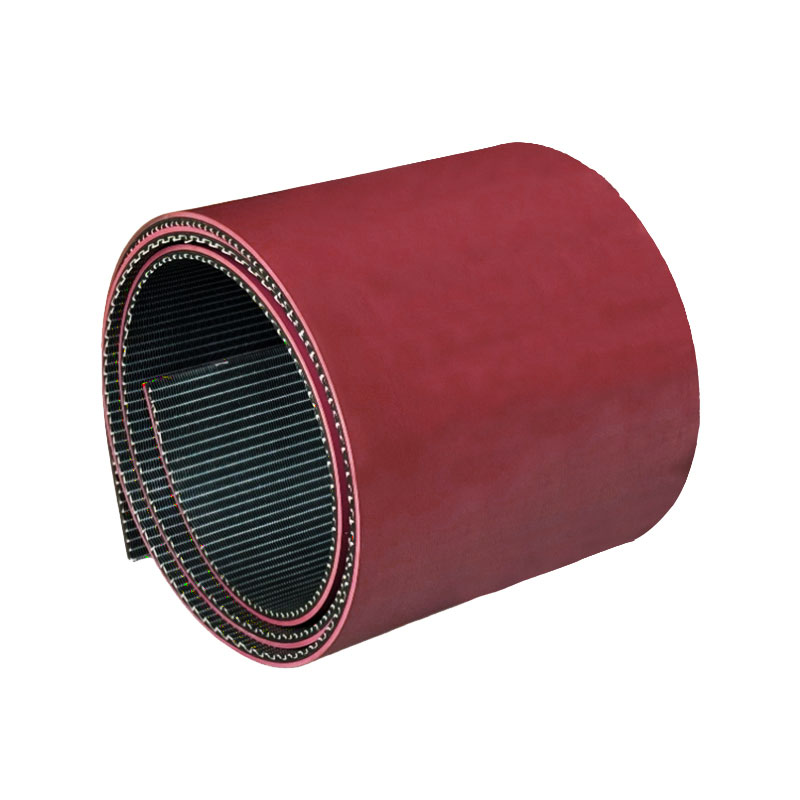

One of the primary reasons rubber is effective in vibration reduction is its excellent damping capability. Unlike metals, which tend to transmit vibrations, rubber absorbs and dissipates vibrational energy as heat through internal molecular friction. Advanced rubber compounds are engineered to optimize this damping behavior across a wide frequency range, allowing them to effectively reduce both low-frequency structural vibrations and high-frequency noise generated at high speeds. Elasticity is another crucial property. High-performance rubber components, such as rail pads, baseplate pads, under-sleeper pads, and vibration isolation mats, can deform under load and quickly recover their original shape. This elastic behavior helps cushion dynamic impacts between the wheel and rail, smoothing force transmission and reducing peak stresses. As a result, track components experience less mechanical shock, improving their service life and reliability.

Durability is especially important in high-speed rail environments, where components are exposed to repeated cyclic loads, temperature variations, moisture, and sometimes oils or chemicals. High-performance rubber is formulated to resist fatigue, aging, and environmental degradation. It maintains stable mechanical properties over long periods, ensuring consistent vibration isolation performance throughout the rail system’s lifecycle. This reliability is essential for reducing unplanned maintenance and ensuring safe, uninterrupted operation. Noise reduction is closely linked to vibration control. Structure-borne noise, which travels through rails and supporting structures, is a major concern in high-speed rail, particularly in urban and residential areas. Rubber-based vibration isolation systems significantly reduce the transmission of these vibrations, helping rail operators meet strict noise regulations and improve the quality of life for communities along rail corridors.

High-performance rubber also supports design flexibility and system optimization. By adjusting material formulations, hardness, thickness, and geometry, engineers can tailor rubber components to meet specific vibration and load requirements for different rail sections, such as bridges, tunnels, turnouts, and stations. This customization enables more precise control over dynamic behavior, which is critical for complex high-speed rail networks.

In addition, the use of rubber-based vibration mitigation contributes to overall system efficiency. Reduced vibration and shock loads lower wear on rails, fasteners, and rolling stock, extending maintenance intervals and reducing life-cycle costs. Improved ride comfort enhances passenger experience, which is a key factor in the competitiveness of high-speed rail as a transportation option. As high-speed rail continues to expand worldwide, the demand for safer, quieter, and more durable infrastructure grows. High-performance rubber materials are no longer auxiliary components but essential engineering solutions. Through superior damping, elasticity, durability, and adaptability, they form the foundation of effective vibration reduction strategies, ensuring that high-speed rail systems operate smoothly, safely, and sustainably for decades to come.