Lightweight Rubber Conveyor Belts: The Future of High-Speed Material Handling

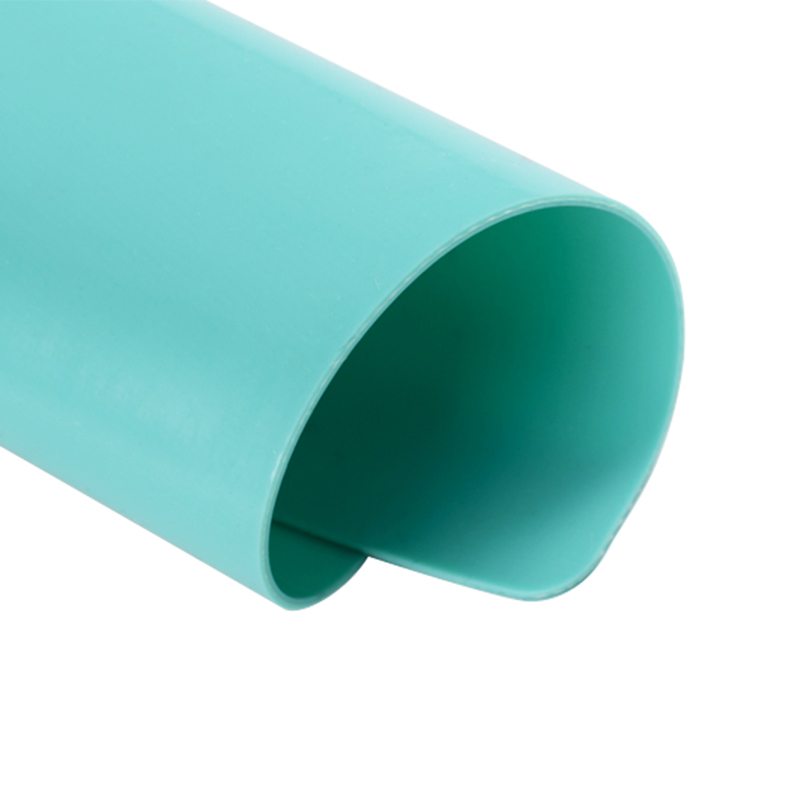

As industries continue to pursue higher productivity, greater automation, and lower operating costs, material handling systems are undergoing rapid transformation. Conveyor belts, as a core component of these systems, play a critical role in determining production speed, reliability, and energy efficiency. Among the various belt solutions available today, lightweight rubber conveyor belts are emerging as the preferred choice for high-speed material handling. With advances in rubber formulation and manufacturing technology, companies like Jiangsu Keqiang New Materials Co., Ltd. are helping redefine the performance standards of modern conveyor systems. Traditional heavy-duty conveyor belts were designed primarily for high-load, low-speed applications. While effective in certain industries, their weight, rigidity, and high energy consumption limit their suitability for fast-moving, precision-oriented production lines. In contrast, lightweight rubber conveyor belts are engineered to provide an optimal balance between strength and flexibility. This makes them particularly well-suited for industries that require rapid transport, accurate positioning, and continuous operation, such as electronics manufacturing, logistics, packaging, food processing, and automated assembly lines.

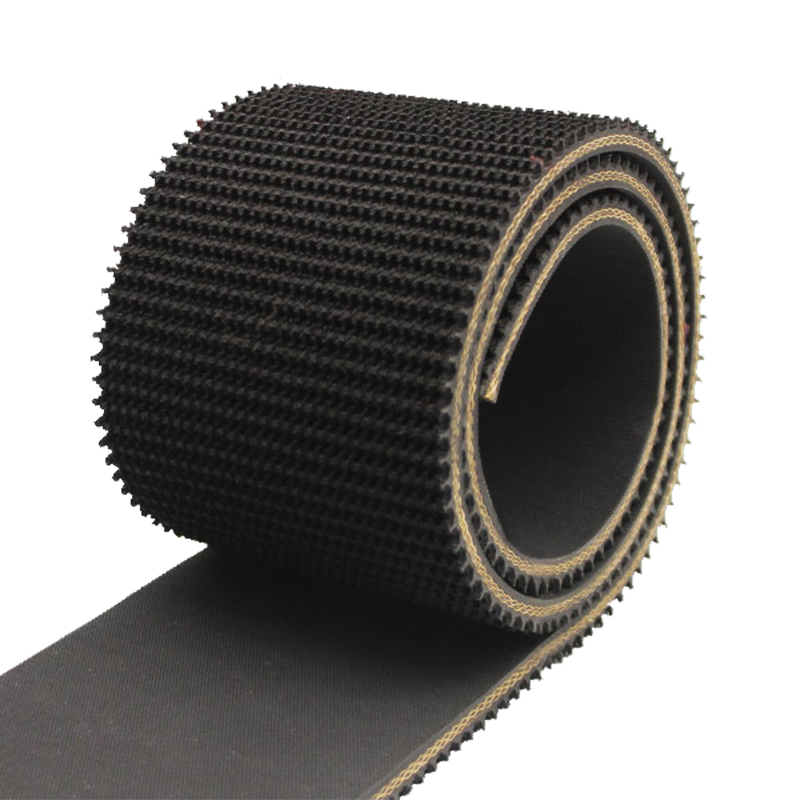

One of the most significant advantages of lightweight rubber conveyor belts is their reduced mass, which directly contributes to higher operating speeds. A lighter belt requires less energy to start, stop, and maintain movement, enabling faster acceleration and deceleration without excessive strain on motors and drive components. This results in improved line speed and reduced energy consumption. Keqiang’s lightweight rubber conveyor belts are designed with optimized rubber compounds and reinforcement structures, ensuring high tensile strength while minimizing unnecessary weight. Flexibility is another key factor that makes lightweight rubber conveyor belts ideal for high-speed material handling. Modern production layouts often include compact conveyor systems with small pulleys, curves, and elevation changes. Traditional belts may struggle in these configurations, leading to increased wear or tracking issues. Keqiang’s belts offer excellent bending performance and dimensional stability, allowing them to operate smoothly across complex conveyor paths. This flexibility supports more efficient factory layouts and enables manufacturers to maximize space utilization.

Durability remains essential even as belts become lighter. High-speed operation increases friction, stress, and wear on conveyor components. Keqiang addresses this challenge through advanced rubber formulations that provide strong abrasion resistance, tear strength, and fatigue resistance. The result is a lightweight belt that maintains long service life even under continuous operation. This durability reduces the frequency of belt replacements and minimizes unplanned downtime—two critical factors for high-output production environments. Another important advantage of lightweight rubber conveyor belts is their low noise and vibration performance. In high-speed material handling systems, excessive noise and vibration can negatively affect working conditions and precision processes. Keqiang’s conveyor belts are engineered to absorb vibration and maintain stable contact with rollers and pulleys. This contributes to smoother operation, lower noise levels, and improved workplace safety, particularly in cleanrooms and automated production facilities.

Precision and stability are also essential in industries that handle delicate or high-value products. Lightweight rubber conveyor belts provide consistent surface friction and accurate tracking, ensuring reliable transport without slippage or misalignment. Keqiang’s manufacturing processes ensure uniform thickness and surface quality, enabling belts to deliver repeatable performance even at high speeds. This precision helps protect products from damage and supports strict quality control requirements. From a maintenance and operational perspective, lightweight rubber conveyor belts offer clear advantages. Their reduced weight makes installation and replacement easier and faster, decreasing labor costs and maintenance time. Additionally, their resistance to oils, chemicals, and environmental aging allows them to perform reliably in a wide range of industrial settings. Keqiang’s conveyor belts are designed to support continuous operation with minimal maintenance, aligning with the needs of modern automated factories.

Energy efficiency is becoming a key consideration for manufacturers worldwide. Lightweight conveyor belts contribute directly to lower power consumption by reducing friction and mechanical load on conveyor systems. Over time, this leads to measurable energy savings and supports sustainable manufacturing practices. For companies focused on reducing their carbon footprint while maintaining high productivity, lightweight rubber conveyor belts offer a practical and effective solution. Looking ahead, the demand for high-speed, intelligent material handling systems will continue to grow. Lightweight rubber conveyor belts are well-positioned to meet these demands, combining speed, durability, precision, and efficiency in a single solution. With its strong R&D foundation and commitment to technological innovation, Jiangsu Keqiang New Materials Co., Ltd. is playing a key role in advancing conveyor belt technology and supporting the future of automated industrial production. As industries evolve toward faster, smarter, and more sustainable operations, lightweight rubber conveyor belts will remain at the forefront of material handling innovation—driving efficiency, reliability, and long-term value for manufacturers worldwide.