Flexible Circuit Board Push Review Version

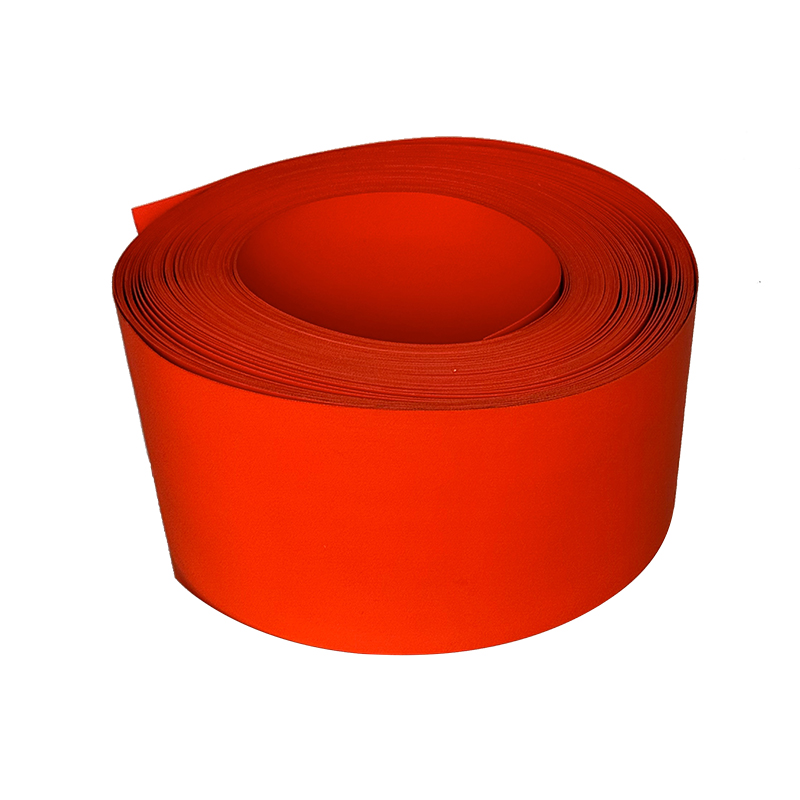

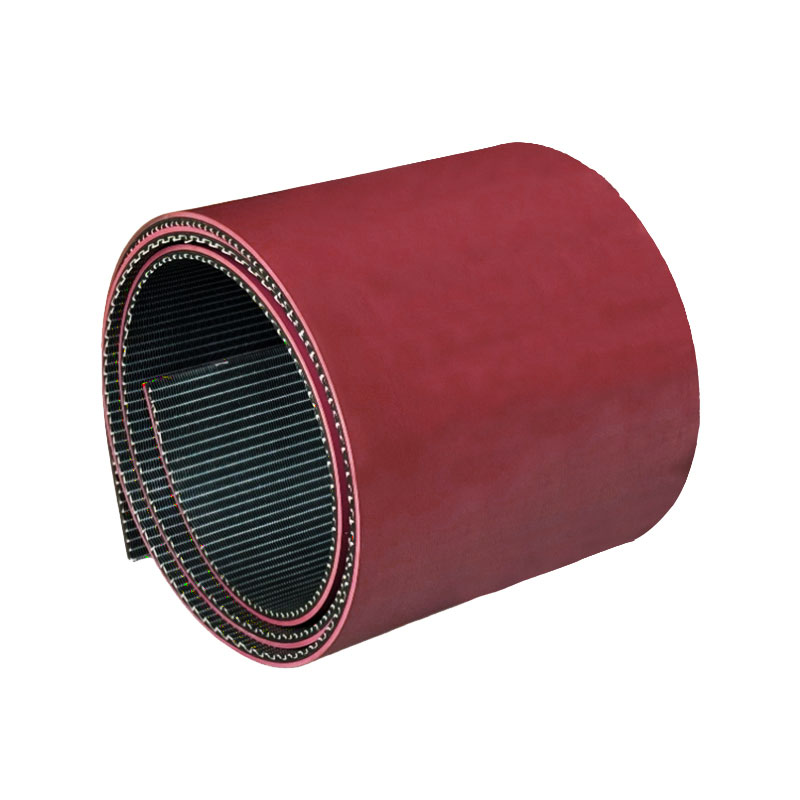

The raw materials imported from Germany are resistant to high temperature and high pressure, meet the process requirements of flexible circuit board lamination, and are professional flexible circuit board consumables

It has rapid and uniform heat conduction, improves the quality of circuit boards, improves production efficiency, saves energy, and saves costs

It has good cushioning and good resilience, avoids scratches caused by hard contact between the heating plate and the laminate, and extends the service life of the heating plate and the laminate

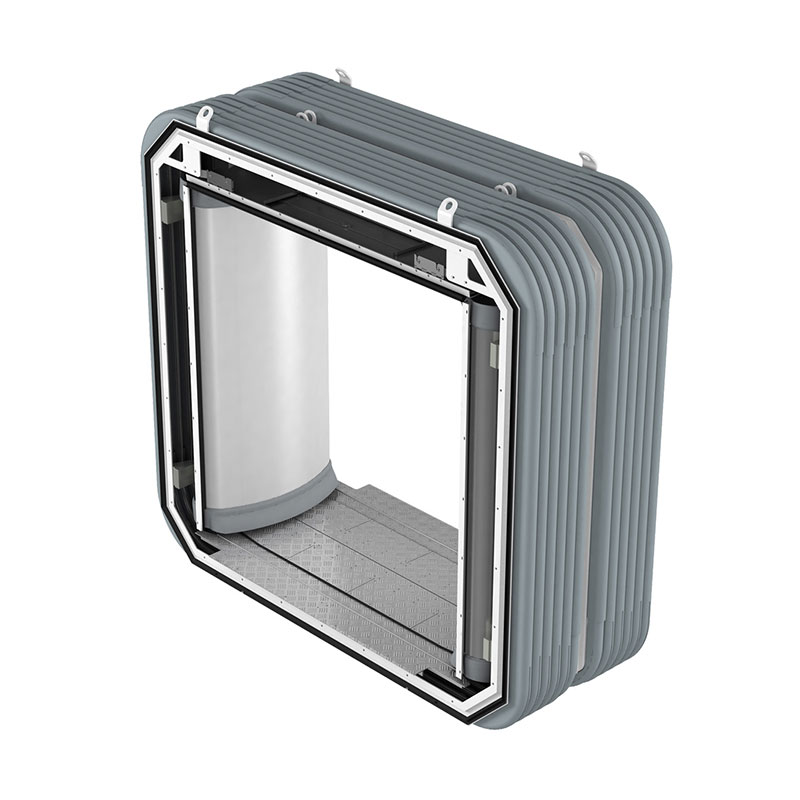

Silicone laminating pad for flexible circuit boards

Silicone laminating pad for flexible circuit boards

●Easy to use, no need for frequent replacement, saving labor hours

●High durability, can be used repeatedly for up to 10 months

Features of COPSIL high-performance laminating buffer heat pad

●Increase product output by 30% during the lamination process

●Fast and uniform heat distribution

●Strong pressure resistance and high durability, reduce static electricity, and improve process conditions

Silicone laminating pad for flexible circuit boards