Why High-Density Rubber Fabrics Are Critical for Heavy-Duty Engineering Projects

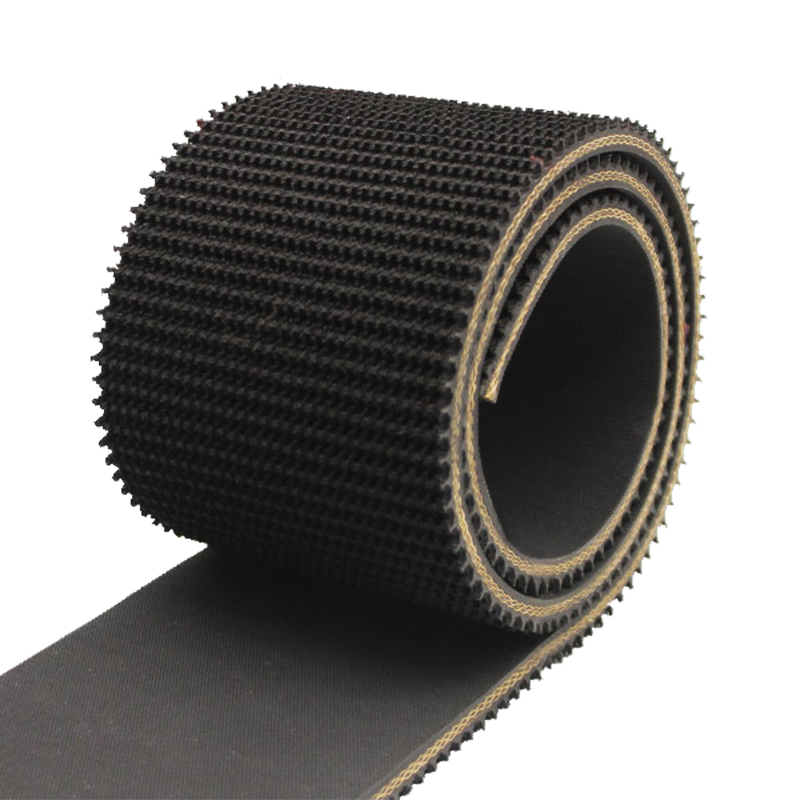

High-density rubber fabrics have become indispensable materials in modern engineering, construction and transportation projects. As industries face more demanding operating conditions, equipment manufacturers and contractors require materials that can withstand stronger forces, higher pressures and more complex environments. High-density rubber fabrics provide the durability, structural stability and performance reliability needed to support these requirements, making them a critical component in today’s heavy-duty applications. At the core of their value is strength. High-density rubber fabrics combine reinforced textile structures with specially formulated elastomers to create an engineered composite with exceptional tensile and tear resistance. Unlike standard fabric layers or traditional rubber sheeting, these materials are designed to resist stretching, distortion or cracking when exposed to extreme mechanical loads. This structural capability makes them ideal for machinery linings, industrial curtains, conveyor backings, and sealing applications where repeated stress is unavoidable.

Another key benefit is environmental resilience. Heavy-duty engineering environments often involve mud, abrasive dust, oils, chemicals and water. Low-grade materials deteriorate quickly under these conditions, leading to equipment damage, leakage or stoppage. High-density rubber fabrics, particularly those produced by advanced manufacturers like Jiangsu Keqiang New Materials, are engineered to resist chemical corrosion, UV radiation, weathering and oxidation. The combination of rubber elasticity and textile reinforcement ensures long-term performance even in harsh open-air or underground environments. Safety is also a driving reason these fabrics are essential. Many engineering projects—tunnels, mines, processing plants, transportation hubs—operate around heavy moving equipment. A failed barrier or torn protective layer can quickly create safety hazards, whether through material falling, machine malfunctioning or accidental exposure to contaminants. Rubber fabrics act as buffers, guards and protective skins that contain risks and reduce the impact of accidental damage. Their inherent flexibility allows them to absorb vibration, impact and pressure better than rigid components.

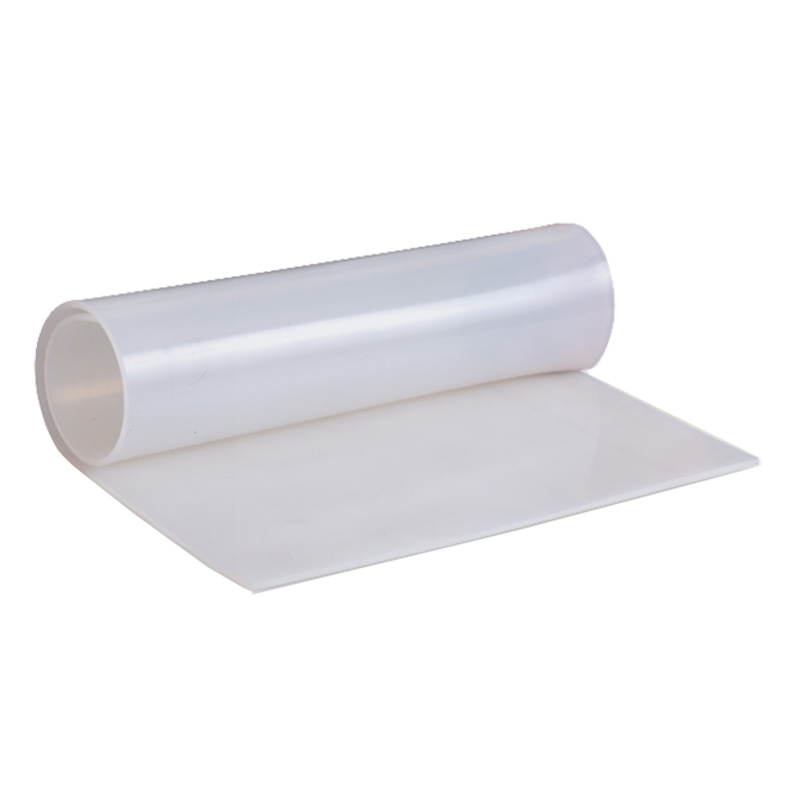

In addition to strength and protection, high-density rubber fabrics support energy and cost efficiency. Traditional materials often need frequent replacement due to cracking, wearing or delamination. With reinforced construction and optimized curing systems, high-density rubber fabrics maintain functional integrity over significantly longer operational cycles. Longer service life means fewer stoppages, reduced labor hours for maintenance and lower lifetime operating costs—major advantages for engineering companies managing tight deadlines and budgets. Another reason these materials are critical is their versatility in manufacturing. High-density rubber fabrics can be produced in multiple structures, including smooth sheets, multilayer composites, woven-reinforced compounds and specialty coated configurations depending on usage needs. This adaptability allows engineers to integrate the same base material system into multiple project elements—sealing, insulation, vibration damping and protective lining—simplifying sourcing while improving performance consistency across equipment.

Their role in enabling innovation cannot be overlooked. As industries adopt faster, heavier, automated machinery and shift toward intelligent manufacturing, traditional materials often struggle to keep pace. High-density rubber fabrics support higher speeds, greater friction loads and tighter tolerances. In material handling systems, for example, stronger fabrics help conveyor belts operate faster without slippage or deformation. In tunneling or mining, they support modern mechanical boring and transportation systems where loads and shock levels far exceed earlier generations of equipment. Finally, these fabrics align with global sustainability priorities. High-performance materials that last longer reduce waste, energy use, and environmental impact. Combined with modern high-precision production, high-density rubber fabrics enable companies to operate responsibly without sacrificing performance or safety, a trend increasingly important in national infrastructure, rail transport and resource development.

In summary, high-density rubber fabrics are more than manufacturing components—they are an integral foundation of heavy-duty engineering reliability. By combining superior strength, reinforced stability, anti-corrosion performance and long service life, these materials ensure that projects can withstand greater demands, perform safely and operate efficiently. As industries continue to evolve, the importance of engineered rubber fabrics will only grow, and manufacturers like Jiangsu Keqiang New Materials Co., Ltd. will remain at the forefront, delivering advanced materials that support the world’s most ambitious engineering challenges.