-

Monday - Friday, 8:00am- 5:00 pm

- +86-13812135827

- shenjia@keqiangtape.com

Monday - Friday, 8:00am- 5:00 pm

Origin: Jiangsu, China

Brand: Keqiang

Certificate: ISO9001,CE SGS

Minimum order quantity: 100 ㎡

Delivery time: 3-7 days

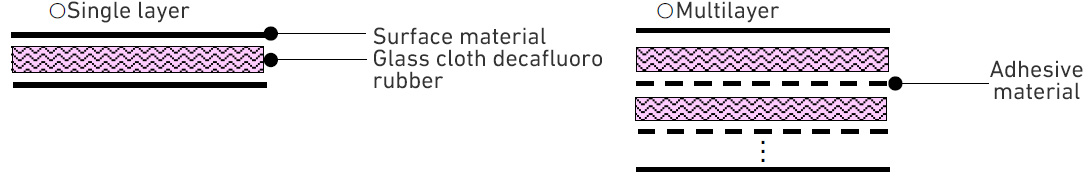

Keqiang high temperature resistant cushion is a porous cushion material made of FRR (fiber reinforced rubber) composed of glass fiber cloth and rubber.

(can be combined with other materials such as rubber upon request)

(1) Excellent low heat resistance The heat-resistant fiber used in the heat-resistant cushion can maintain its good quality even in a long-term high-temperature working environment of 250℃, without aging, agglomeration, or performance change.

(2) Long service life It is mainly made of heat-resistant fiber, woven by advanced three-dimensional precision needle implantation method, with strong and stable structure, not easy to fall off, damage or deform, and has good dimensional properties. It can meet the customer's desire to improve economic benefits.

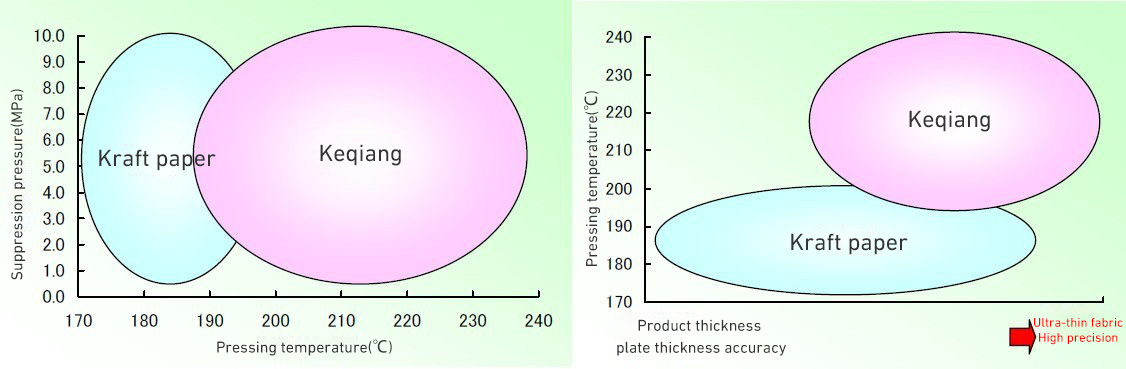

(3) Balanced heat conduction and pressure transmission quality are stable, and can stably transmit the temperature and pressure of various laminated board pressing processes.

(4) Wide application The product series is complete, whether it is various fire-resistant boards, CCL (paper-based CCL). Appropriate products can be provided for customers to use.

(5) Good thickness change stability The use of cutting-edge high-density needle implantation structure can maintain a certain thickness change and resilience during high temperature and high pressure bonding.

(6) Easy to operate. In the lamination process of fire-resistant board, it is easy to change the equipment, and the downtime is short when changing. It has higher production efficiency than using kraft paper. It can also be applied to automated production equipment (automatic handling), saving a lot of manpower costs for the company.

(7) Low static electricity generation rate. During the lamination process of fire-resistant board, no static electricity is generated, which can prevent dust pollution.

(8) Non-toxic and high safety. The heat-resistant cushion will not release toxic substances or odor during the lamination process.

(9) No environmental pollution problem. The heat-resistant cushion can be directly carbonized under the high temperature of combustion, and the combustion product will not release toxic gas, and the waste is easy to handle.