The Role of Tunnel Fabrics in Modern Infrastructure Construction

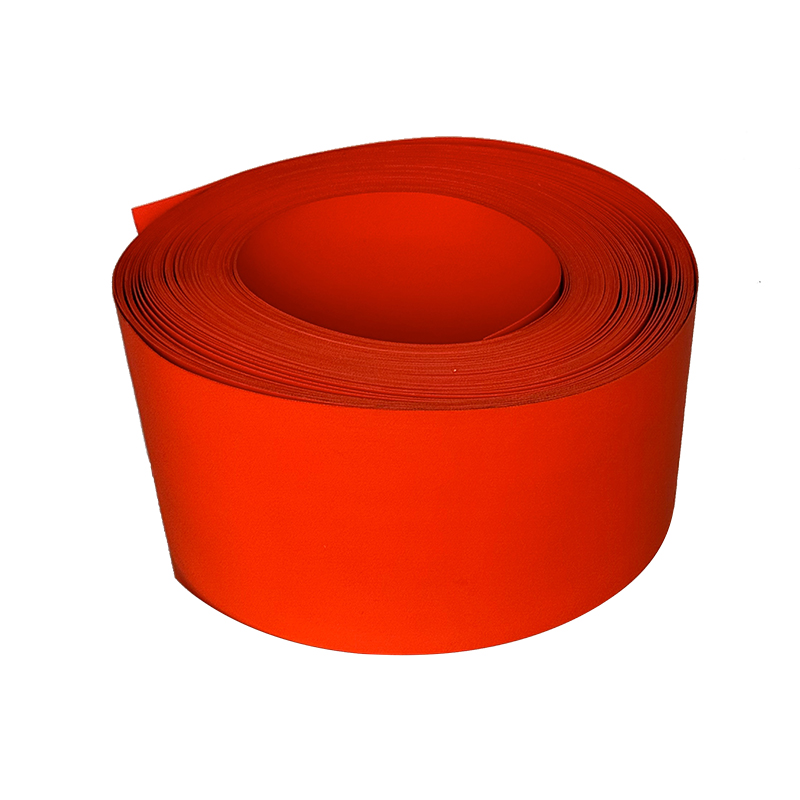

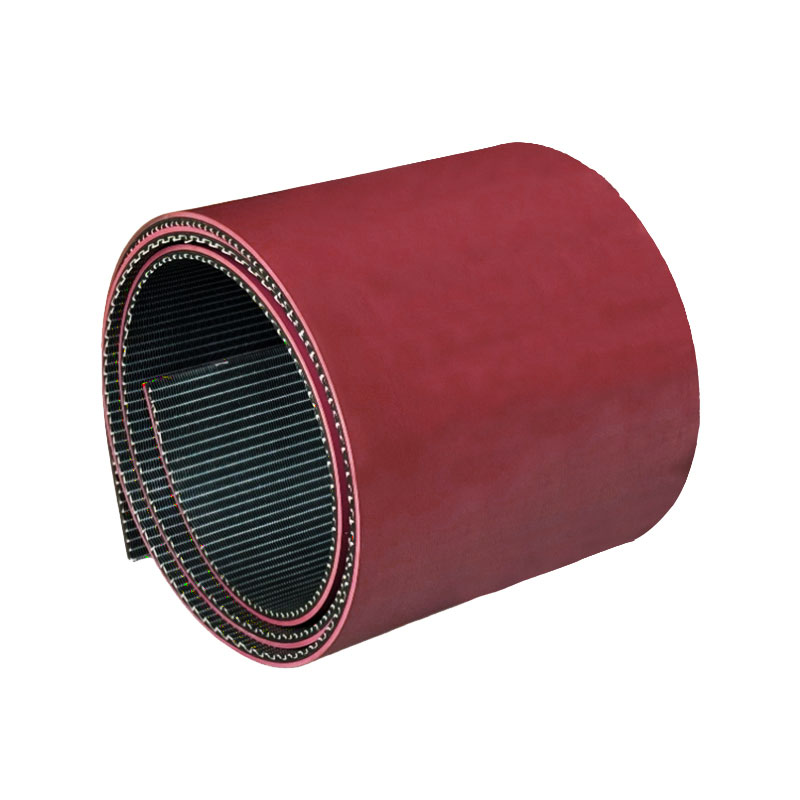

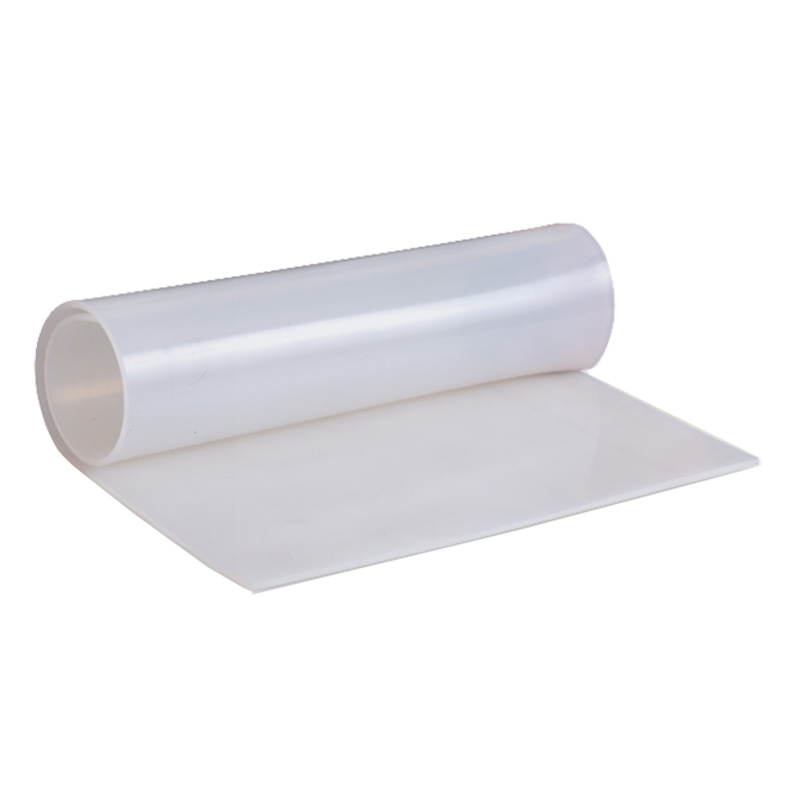

Tunnel construction is one of the most demanding areas of modern infrastructure development, requiring materials that can withstand extreme mechanical stress, harsh environmental conditions, and long service cycles. Among these materials, tunnel fabrics play a crucial yet often overlooked role. These high-performance industrial fabrics are engineered to deliver strength, flexibility, and durability, making them indispensable in underground engineering projects such as subways, rail tunnels, highways, hydropower systems, and mining operations. Tunnel fabrics are typically used as reinforcement and protective layers in various construction processes. They are integrated into waterproofing membranes, lining systems, ventilation ducts, and protective covers. Their main function is to enhance structural integrity while providing resistance against moisture, chemicals, abrasion, and pressure. In underground environments where water seepage, rock friction, and temperature fluctuations are common, ordinary materials fail quickly. High-tech tunnel fabrics, however, are designed specifically to maintain performance under these challenging conditions.

One of the most important characteristics of tunnel fabrics is their high tensile strength. During tunnel excavation and lining installation, materials are subjected to pulling forces, deformation, and mechanical impact. Reinforced rubber or polymer-coated fabrics provide the strength needed to resist tearing and stretching. This ensures that membranes and protective systems remain intact, which is essential for long-term tunnel safety. A failure in these layers could lead to leakage, corrosion, or even structural damage, resulting in costly repairs and operational disruptions. Waterproofing is another critical function. Underground structures constantly face groundwater pressure and moisture intrusion. Tunnel fabrics used in waterproofing systems act as reinforcement for membranes, helping them maintain shape and performance under hydrostatic pressure. Their dimensional stability prevents cracks and weak points, ensuring a continuous barrier against water penetration. This is especially vital in railway and metro tunnels, where water leakage can compromise electrical systems, track stability, and passenger safety.

Chemical resistance also plays a major role in the effectiveness of tunnel fabrics. Soil, groundwater, and industrial environments often contain chemicals that can degrade standard materials. Advanced rubber-coated or specially treated fabrics resist acids, alkalis, and other corrosive agents. This extends service life and reduces the need for frequent maintenance or replacement. In large-scale infrastructure projects, durability directly translates into cost savings and improved reliability over decades of operation. Flexibility combined with strength is another reason tunnel fabrics are essential. Tunnel surfaces are not always perfectly smooth, and structures may shift slightly over time due to ground movement or load changes. Fabrics with good flexibility can adapt to these movements without cracking or losing performance. This adaptability ensures that protective and sealing systems continue functioning even under dynamic conditions, which is particularly important in seismic regions or soft soil environments.

Tunnel fabrics also contribute to construction efficiency. Lightweight yet strong materials are easier to transport, handle, and install compared to rigid alternatives. Faster installation reduces project timelines and labor costs. In complex tunnel projects where logistics are challenging, the use of advanced fabrics simplifies operations and enhances overall construction productivity. In addition, safety is significantly improved through the use of high-quality tunnel fabrics. Reliable reinforcement and waterproofing reduce the risk of structural failures, leaks, and hazardous working conditions. Long-term stability of tunnel systems ensures safer transportation networks and infrastructure for communities. As cities expand and underground construction increases, the importance of dependable material solutions continues to grow.

Modern infrastructure projects demand materials that combine performance, longevity, and efficiency. Tunnel fabrics meet these requirements by offering a balanced combination of mechanical strength, environmental resistance, flexibility, and ease of use. Their role may not always be visible once a project is completed, but they form a critical foundation that supports the safety and durability of underground structures. As technology advances, the development of even higher-performance fabrics will continue to drive innovation in tunnel engineering and large-scale infrastructure construction.