How Keqiang Conveyor Belts Improve Safety and Reduce Downtime

In modern industrial environments, conveyor systems are the backbone of efficient production and material handling. Whether in electronics manufacturing, logistics, food processing, or automated assembly lines, conveyor belts must operate reliably, safely, and continuously. Any unexpected failure not only disrupts production but can also pose serious safety risks to workers. Recognizing these challenges, Jiangsu Keqiang New Materials Co., Ltd. has developed high-performance conveyor belt solutions designed to enhance operational safety while significantly reducing downtime across a wide range of industries. Safety begins with material stability. Traditional conveyor belts can suffer from surface cracking, edge fraying, or uneven wear over time, increasing the risk of sudden belt failure. Keqiang conveyor belts are engineered using advanced rubber formulations that provide excellent tensile strength, abrasion resistance, and fatigue performance. These properties ensure structural integrity even under continuous high-speed operation, reducing the likelihood of belt breakage or unexpected shutdowns that could endanger personnel and equipment.

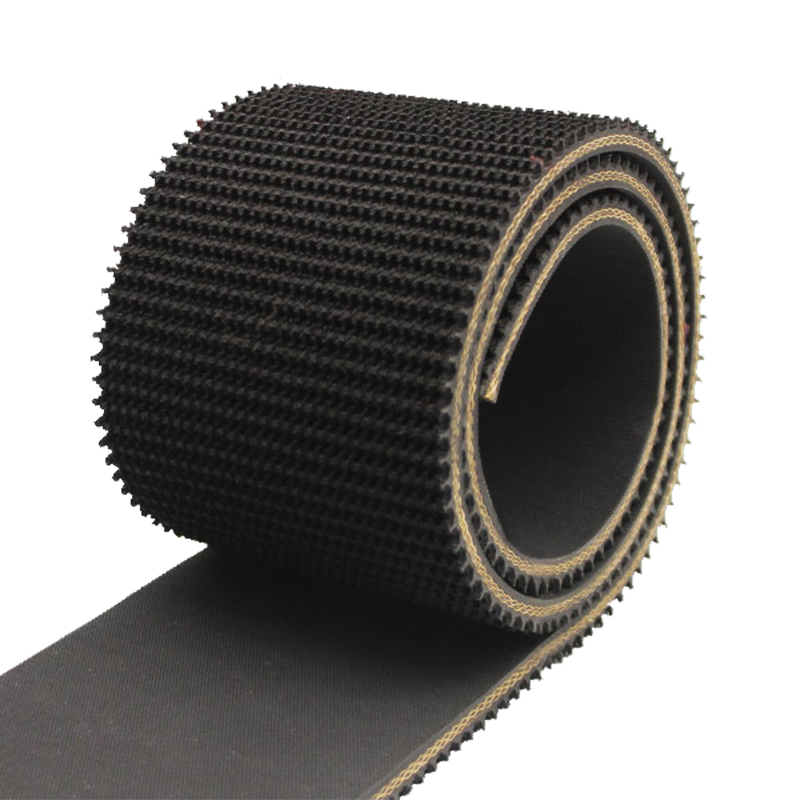

Another critical safety factor is belt tracking and dimensional stability. Misaligned or unstable conveyor belts can cause material spillage, equipment damage, and worker injuries. Keqiang places strong emphasis on precision manufacturing, ensuring uniform thickness and balanced reinforcement structures in every belt. This precision allows the belts to track accurately on pulleys and rollers, minimizing lateral movement and reducing the need for frequent manual adjustments. Stable tracking not only improves safety but also extends the service life of conveyor components. Slip resistance is equally important, especially in environments where precise positioning and controlled movement are required. Keqiang conveyor belts are designed with optimized surface friction characteristics that prevent material slippage without causing excessive wear. This ensures smooth and predictable material transport, even at high speeds. In automated production lines, reliable grip reduces the risk of product jams or sudden stops, which are common causes of downtime and safety incidents.

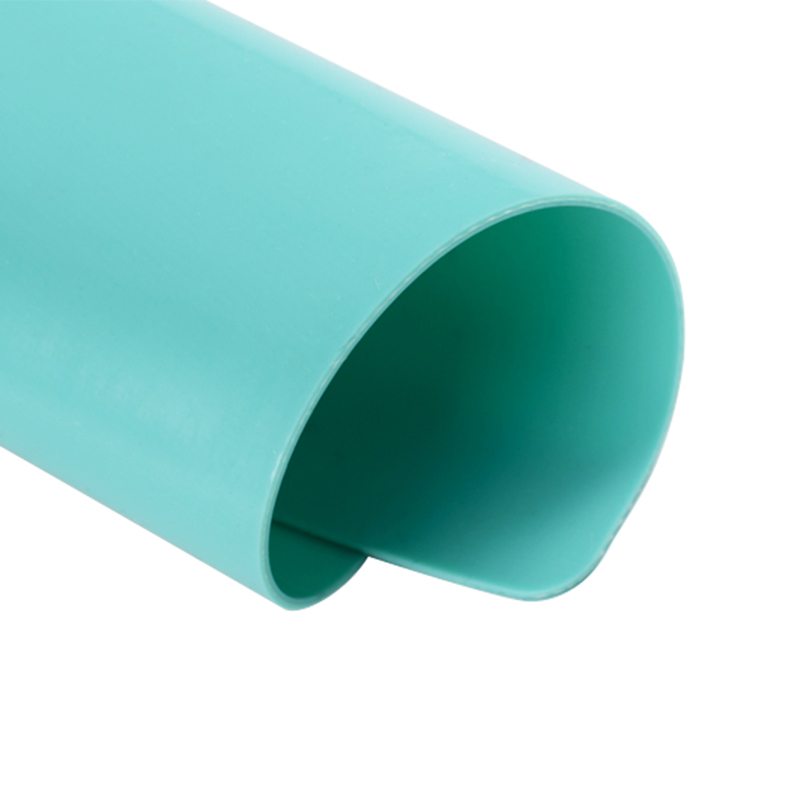

Durability plays a direct role in minimizing downtime. Frequent belt replacements interrupt production schedules, increase maintenance costs, and create potential safety hazards during installation. Keqiang conveyor belts are built for long service life, resisting wear, tearing, and deformation over extended operating periods. Their ability to withstand continuous stress reduces the frequency of maintenance interventions, allowing production lines to run longer and more consistently without unplanned stoppages. Environmental resistance further enhances both safety and reliability. Industrial environments often expose conveyor belts to oils, chemicals, moisture, and temperature variations. Traditional belts may degrade under such conditions, leading to surface damage or loss of mechanical strength. Keqiang’s conveyor belts feature strong resistance to corrosion, aging, and chemical exposure, ensuring stable performance even in challenging environments. This resilience helps prevent sudden belt failures that could result in equipment damage or worker injury.

Noise and vibration control are often overlooked aspects of conveyor safety. Excessive noise and vibration can contribute to worker fatigue, reduce concentration, and accelerate mechanical wear. Keqiang conveyor belts are designed to operate smoothly, absorbing vibration and maintaining consistent contact with conveyor components. Reduced vibration not only improves workplace comfort but also protects motors, bearings, and rollers from premature wear, further reducing the risk of system failure and downtime. Ease of maintenance is another key advantage of Keqiang conveyor belts. Their lightweight design and stable structure make installation, inspection, and replacement safer and more efficient. Maintenance personnel can perform routine checks and belt changes more quickly, reducing exposure to potential hazards and shortening maintenance windows. This user-friendly design supports safer working conditions and helps factories maintain uninterrupted production schedules.

In high-speed and automated systems, even minor belt inconsistencies can trigger sensor alarms or emergency stops. Keqiang addresses this by delivering conveyor belts with consistent performance and reliable operational characteristics. Their belts integrate seamlessly with modern automated control systems, reducing false alarms and ensuring smoother operation. This reliability is essential for manufacturers aiming to achieve high output while maintaining strict safety standards. Ultimately, Keqiang conveyor belts improve safety and reduce downtime by combining advanced material science, precision manufacturing, and application-focused design. By preventing common failure modes, ensuring stable operation, and supporting easy maintenance, these belts help manufacturers create safer, more efficient production environments. Reduced downtime leads to higher productivity, lower operating costs, and improved return on investment.

As industries continue to pursue automation, speed, and reliability, the importance of safe and dependable conveyor systems will only increase. With its strong commitment to technological innovation and customer-focused solutions, Jiangsu Keqiang New Materials Co., Ltd. remains a trusted partner for businesses seeking conveyor belt solutions that protect people, safeguard equipment, and keep production moving without interruption.