How Silicone Rubber Sheets Improve Efficiency in PV Module Lamination

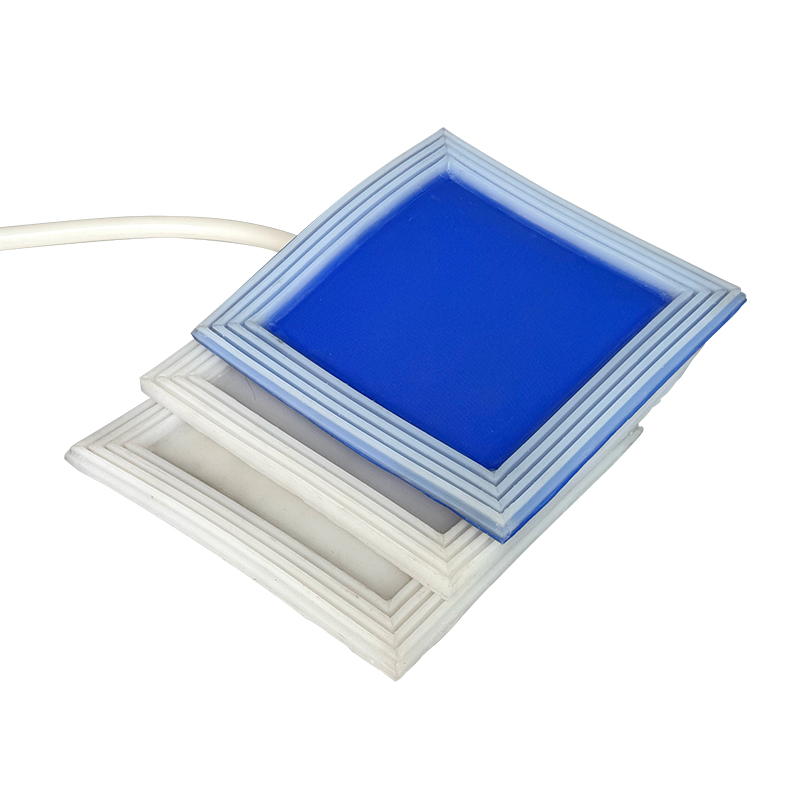

As the global demand for photovoltaic (PV) modules continues to rise, manufacturers are constantly seeking ways to enhance production efficiency, ensure product reliability, and reduce operational costs. One component that plays an essential role in the lamination process—but is often overlooked—is the silicone rubber sheet. In PV module laminators, silicone rubber sheets act as the crucial interface layer that ensures uniform pressure, stable temperature transfer, and long-lasting performance throughout continuous production cycles. For companies like Jiangsu Keqiang New Materials Co., Ltd., which specialize in high-performance silicone sheets, this material has become a key driver of efficiency in modern solar module manufacturing. The PV lamination process involves EVA or POE encapsulant melting and bonding layers of glass, cells, and backsheet into a structurally integrated module. This requires uniform pressure and precise heat transfer across the entire surface of the module. Silicone rubber sheets, positioned inside the laminator press chambers, provide this exact combination of elasticity, durability, and thermal stability. Without a high-quality silicone sheet, the module can suffer from uneven encapsulation, air pockets, incomplete bonding, or defective edges—leading to product loss and higher production costs.

One of the primary ways silicone rubber sheets improve efficiency in PV module production is through their exceptional heat resistance and thermal stability. The lamination process typically involves temperatures between 140°C and 160°C. Silicone sheets maintain consistent performance under prolonged exposure to such heat without hardening, cracking, or deforming. High-quality sheets from Keqiang are engineered with uniform heat conduction properties, ensuring that every module receives consistent temperature distribution. This uniform thermal environment reduces lamination defects, shortens processing time, and stabilizes cycle-to-cycle performance. Another crucial advantage is the excellent elasticity and resilience of silicone rubber. During lamination, modules of varying thicknesses and designs pass through the machine. The silicone sheet must adapt to these differences and provide equal compression across the surface. Keqiang’s silicone sheets offer high tear resistance, strong rebound behavior, and outstanding surface uniformity. These characteristics ensure that each lamination cycle applies stable pressure, resulting in better encapsulation quality and fewer production interruptions.

Durability is another factor that directly influences efficiency. Low-quality silicone sheets may degrade quickly, leading to frequent replacements, increased downtime, and inconsistent lamination outcomes. Keqiang’s silicone rubber sheets are designed for long-term use, resisting aging, chemical corrosion, and thermal wear. Their high mechanical strength allows them to withstand thousands of cycles without significant changes in elasticity or thickness. For PV manufacturers operating at high production speeds, this durability translates into reduced maintenance time and lower operational costs. Silicone rubber sheets also contribute to lamination efficiency by preventing contamination and ensuring a clean production environment. Their smooth, non-stick surface reduces the risk of EVA residue, film particles, or dust sticking to the sheet. This not only keeps the module surface clean but also reduces the need for frequent cleaning, which is a major cause of equipment downtime in many PV factories. The stability and cleanliness of Keqiang’s silicone sheets support continuous operation and help maintain consistent module quality.

In modern PV manufacturing, the ability to handle large-format and ultra-thin modules is becoming increasingly important. These new module designs require precise control over lamination pressure and temperature. Keqiang’s silicone rubber sheets are engineered with excellent thickness uniformity, ensuring that even extra-large or lightweight modules receive the same lamination quality as standard sizes. This capability helps manufacturers transition to next-generation module formats without needing to modify their laminators extensively. Another critical aspect linked to efficiency is energy consumption. Silicone sheets with poor heat transfer properties require longer lamination times or higher temperatures to achieve proper melting and bonding. Keqiang’s advanced formulations enhance heat transfer efficiency, allowing laminators to complete cycles faster while maintaining optimal encapsulation results. The result is a measurable reduction in energy usage per module—an advantage that becomes significant in high-volume production environments.

Ultimately, silicone rubber sheets serve as a small but vital component that directly influences product yield, production speed, and operational costs. For PV manufacturers striving for efficiency, reliability, and competitiveness, selecting a high-performance silicone sheet is just as important as choosing the right encapsulant, laminator, or backsheet material. Jiangsu Keqiang New Materials Co., Ltd. has spent years perfecting its silicone rubber sheet technology to meet these needs, providing global customers with materials that withstand demanding lamination conditions while delivering value and performance. In an industry where every second of production time matters, high-quality silicone rubber sheets help manufacturers maintain smooth operation, reduce waste, and achieve higher output. As PV technology and manufacturing continue to evolve, the importance of durable, high-precision silicone materials will only grow, reinforcing their essential role in supporting the world’s transition to clean energy.