Exploring the Durability of Silicone Sheets in Vacuum Press and Hot Press Applications

In modern industrial manufacturing, vacuum press and hot press technologies are widely used in applications such as photovoltaic module production, glass lamination, composite molding, woodworking panels, and advanced material processing. These processes demand materials that can withstand extreme temperatures, repeated pressure cycles, and long operating hours without performance degradation. Among all elastic interface materials, silicone rubber sheets have proven to be the most reliable solution. Jiangsu Keqiang New Materials Co., Ltd., with its expertise in high-performance rubber materials, has developed silicone sheets specifically engineered for durability in demanding vacuum press and hot press environments. Vacuum press and hot press systems operate under harsh conditions. During operation, silicone sheets are exposed to high temperatures, often ranging from 140°C to over 200°C, while simultaneously enduring continuous compression and vacuum suction. Traditional rubber sheets tend to harden, deform, or crack under such conditions, leading to uneven pressure distribution and compromised product quality. Silicone rubber sheets, however, possess a unique polymer structure that allows them to maintain flexibility and strength even after prolonged exposure to heat and pressure, making them ideal for long-term industrial use.

One of the most important durability advantages of silicone sheets lies in their exceptional thermal aging resistance. Keqiang’s silicone rubber sheets are formulated to resist molecular breakdown caused by high temperatures. Unlike conventional rubber, which experiences rapid aging and loss of elasticity, silicone maintains its mechanical properties over extended periods. This thermal stability ensures that the sheets retain consistent thickness and rebound behavior, even after thousands of pressing cycles, significantly extending their service life in vacuum and hot press applications. Compression set resistance is another critical factor influencing durability. In vacuum press systems, silicone sheets are repeatedly compressed and released. If the material fails to recover its original shape, pressure becomes uneven, leading to product defects. Keqiang silicone sheets are engineered with low compression set characteristics, meaning they recover quickly and completely after each cycle. This resilience allows manufacturers to maintain stable production quality without frequent material replacement or machine recalibration.

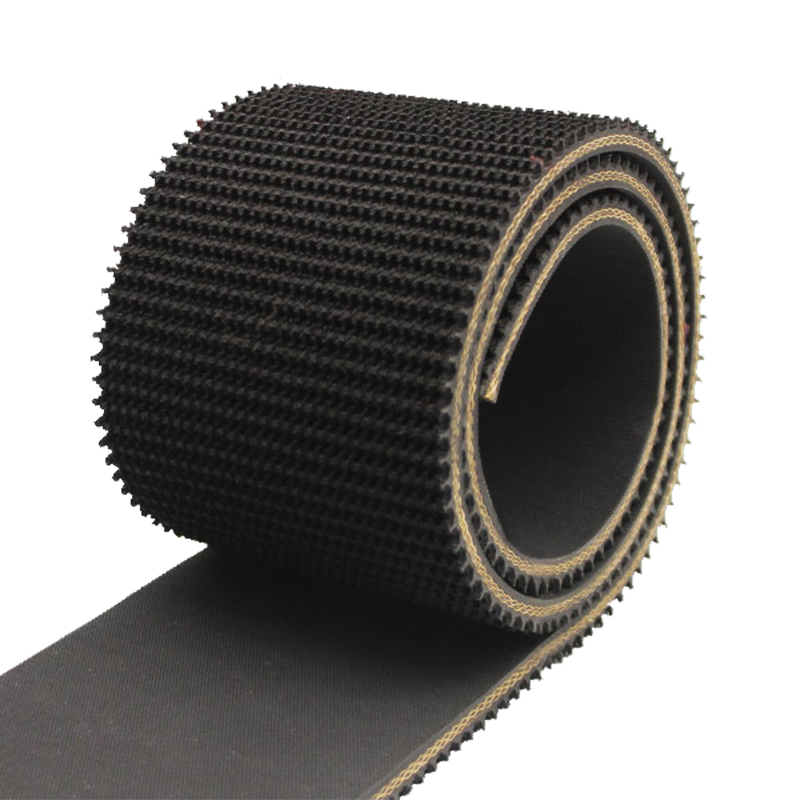

Mechanical strength also plays a vital role in durability. Vacuum and hot press applications often involve large-format materials and uneven load distribution. Keqiang’s silicone sheets are reinforced with optimized formulations that provide high tear strength and tensile performance. This prevents tearing, edge damage, and surface cracking—common issues seen with lower-quality rubber sheets. The enhanced mechanical integrity ensures that the sheets remain intact even in high-stress production environments. Chemical and environmental resistance further contribute to the long-term durability of silicone sheets. In many press applications, materials such as adhesives, resins, and release agents are present. Traditional rubber can swell or degrade when exposed to these substances, but silicone rubber exhibits excellent resistance to chemicals, oxidation, ozone, and UV exposure. Keqiang’s silicone sheets maintain stable performance in both cleanroom and industrial environments, reducing the risk of unexpected failures.

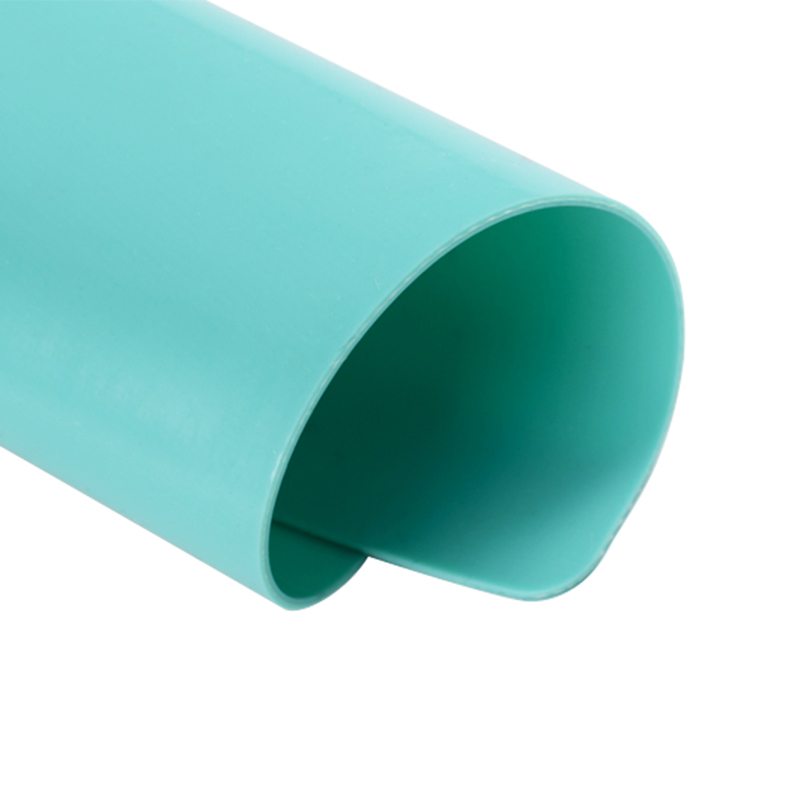

Surface stability is another often overlooked aspect of durability. Over time, some rubber sheets develop surface contamination, stickiness, or uneven textures that affect product appearance. Keqiang’s silicone sheets feature a smooth, non-stick surface that resists residue buildup and minimizes contamination. This property reduces cleaning frequency, protects finished products, and supports continuous operation in high-efficiency production lines. Thickness uniformity and dimensional stability also influence durability in vacuum and hot press applications. Uneven thickness leads to localized stress points, accelerating material fatigue. Keqiang utilizes advanced calendaring and precision molding processes to ensure consistent thickness across the entire sheet. This uniformity distributes pressure evenly, reducing wear and extending the usable lifespan of the silicone sheet.

From a cost-efficiency perspective, the durability of Keqiang silicone sheets delivers long-term value. Although high-performance silicone materials may have a higher initial cost compared to traditional rubber sheets, their extended lifespan, reduced downtime, and lower maintenance requirements significantly reduce total operating costs. Manufacturers benefit from fewer replacements, stable production schedules, and improved product yield. In conclusion, the durability of silicone sheets is a decisive factor in the performance of vacuum press and hot press systems. Keqiang silicone rubber sheets excel through superior thermal resistance, elasticity retention, mechanical strength, and chemical stability. These properties ensure reliable operation under extreme conditions and make them a preferred choice for manufacturers seeking consistent quality and long-term efficiency. As industrial processes continue to demand higher performance and greater reliability, Jiangsu Keqiang New Materials Co., Ltd. remains committed to advancing silicone sheet technology to support the evolving needs of global manufacturing industries.