Material Science Behind High-Performance Silicone Rubber Sheets

Silicone rubber sheets have become essential materials across industries ranging from electronics, automotive, and aerospace to food processing and energy equipment. Their popularity is not simply based on flexibility and heat resistance—these engineered materials are the result of deep innovation in polymer chemistry, compounding technology, and precision manufacturing. Understanding the material science behind high-performance silicone sheets reveals why they outperform conventional rubbers and continue to expand into demanding industrial applications.

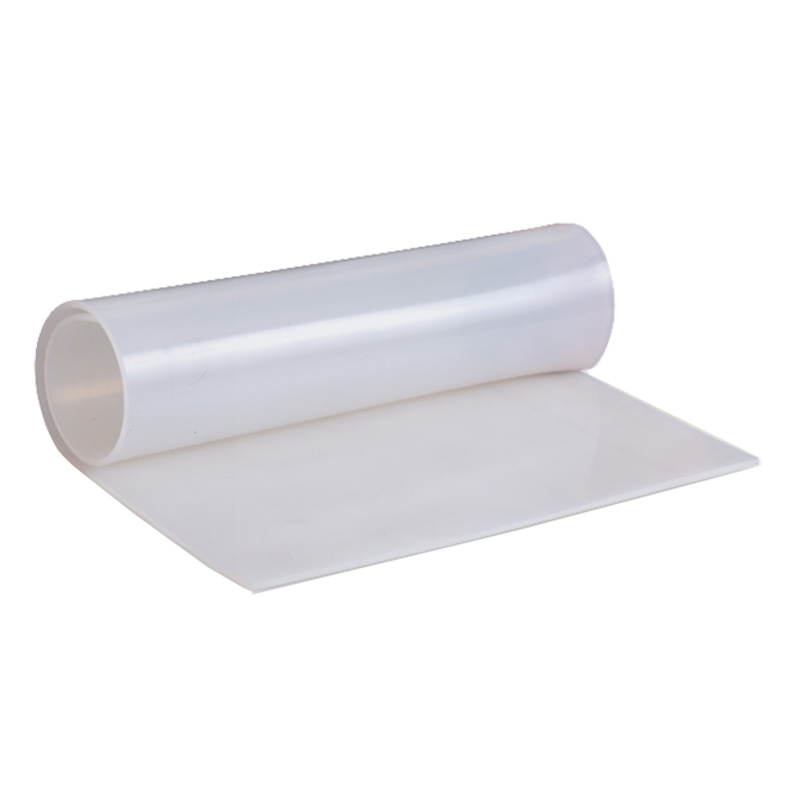

At the core of silicone rubber is its unique molecular structure. Silicone is based on a silicon-oxygen (Si–O) backbone rather than the traditional carbon-carbon chains found in natural and synthetic rubbers. This Si–O bond is significantly stronger and more thermally stable than C–C bonds, allowing silicone materials to endure extreme temperatures without degrading. Typical silicone formulations remain elastic from –60°C to 250°C, and special grades can withstand even higher intermittent temperatures. This stability allows silicone sheets from Jiangsu Keqiang New Materials to perform reliably in hot press molding, solar lamination, vacuum forming, and thermal insulation settings where traditional rubbers quickly fail.

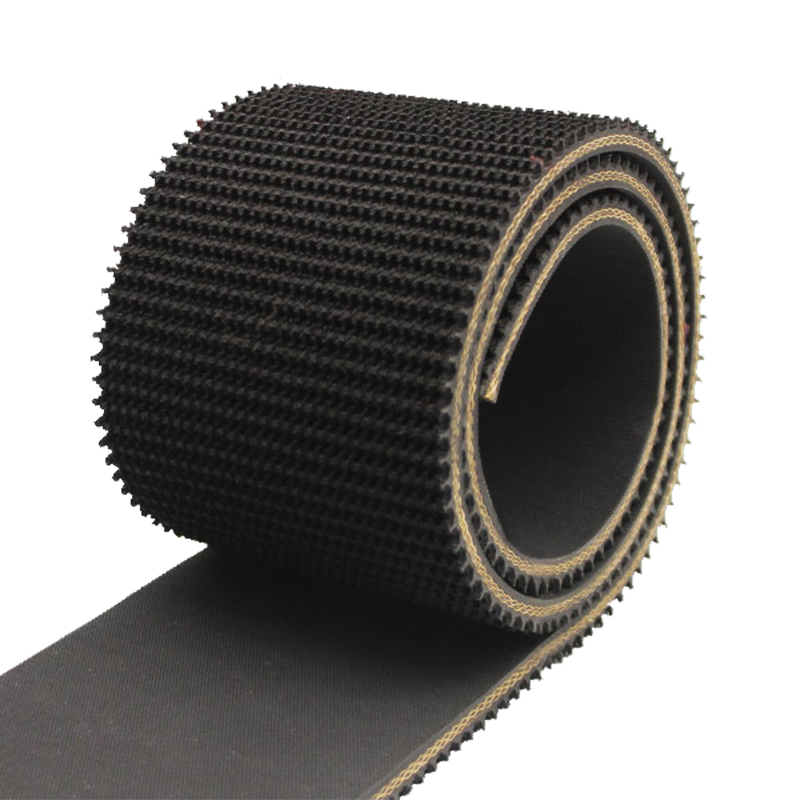

Material science also plays a critical role in optimizing mechanical properties. Raw silicone elastomer must be compounded with reinforcing fillers—most commonly fumed silica—which improves tensile strength, tear resistance, and abrasion durability. At Keqiang, careful control of filler particle size and uniform dispersion ensures a fine balance between flexibility and strength. This is essential for applications where sheets are repeatedly stretched, compressed, bent, or vacuum-formed during manufacturing cycles. Crosslinking, or vulcanization, is another key contributor to silicone sheet performance. Silicone elastomers are typically cured using peroxide systems or platinum-catalyzed addition curing. Each process yields different performance advantages. Peroxide-cured silicone provides excellent heat resistance and is widely used in industrial presses. Platinum-cured silicone offers superior purity, low shrinkage, and compliance with food and medical contact standards. Keqiang leverages the curing system best suited to customer applications, ensuring that every sheet delivers consistent elasticity, tear strength, and compression set properties.

Thermal insulation and conductivity are also engineered characteristics of silicone. Depending on formulation, silicone rubber exhibits excellent thermal stability with low thermal conductivity, making it suitable as a high-temperature gasket or insulator. However, specialized grades can incorporate conductive fillers such as ceramic powders, metal oxides, or graphite to enhance heat transfer. This allows silicone sheets to function in electronic heat dissipation or heated platen systems, demonstrating how compounding science can fundamentally change performance characteristics. Chemical resistance further distinguishes silicone rubber from conventional materials. Silicone resists oxidation, ozone, UV radiation, and most chemicals, thanks to the inert nature of the silicon-oxygen backbone. Where petrochemical-based rubbers degrade when exposed to oils, acids, or weathering, silicone maintains long-term flexibility and dimensional stability. This resilience supports long product life cycles, reduces maintenance, and ensures dependable sealing or cushioning performance in harsh industrial environments.

In addition to mechanical and thermal strengths, silicone possesses low toxicity and excellent environmental stability. Unlike rubbers containing plasticizers or added stabilizers that leach or evaporate over time, silicone remains chemically stable. Keqiang’s advanced processing also ensures minimal volatile content and superior aging resistance—a critical requirement for industries such as pharmaceuticals, food handling, and clean vacuum forming environments. Advanced silicone rubber sheets can also be modified to meet specific engineering challenges. With the incorporation of specialty additives, Keqiang can tailor silicone sheets to deliver flame retardancy for safety-critical environments, anti-static or conductive performance for electronics, closed-cell or sponge structures for cushioning and sealing, or enhanced tear reinforcement for repeated hot-press cycling. These innovations demonstrate how silicone’s base chemistry provides a customizable platform rather than a one-size-fits-all material.

Ultimately, the high performance of silicone sheets is not accidental—it's rooted in the deliberate application of polymer science, filler technology, and precision curing. By combining these elements, Jiangsu Keqiang New Materials Co., Ltd. delivers rubber sheets that withstand extreme temperatures, pressure, and chemical exposure while maintaining elasticity and durability. As industries continue to demand faster, cleaner, and more energy-efficient processes, silicone rubber materials will play an increasingly critical role. With ongoing investment in formulation research and material innovation, Keqiang remains committed to advancing silicone material science and helping customers achieve higher reliability, longer equipment life, and better production outcomes.